Products

- Metal Casting

- Die Casting

- Sand Casting

- Gravity Casting

- Investment Casting

- Non Ferrous Casting

- Metalworking Service

- Metal Fabrication

- Sheet Metal Fabrication

- Metal Welding

- Metal Cutting

- Metal Bending

- Metal Plate Rolling

- Metal Roll Forming

- Metal Stamping

- Deep Drawn Stamping

- Expanded Sheet Metal

- Metal Perforating

- Plastic Molding

- Injection Molding

- Rotational Molding

- Blow Molding

- Thermoforming

- Precision CNC Machining

- EDM Machining

- Heat Treatment

- Surface Treatment

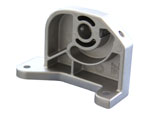

Die Casting

The die casting is suitable for applications that require good surface finish and dimensional consistency. The main die casting alloys are: zinc, aluminium, copper, magnesium, lead, and tin etc. Manufacture of parts using die casting is relatively simple, which keeps the incremental cost per item low. It is especially suited for a large quantity of small to medium sized castings.

Applications:

We can make die casted hinges, locks, automobile parts, motorcycle parts, gear box, lighting fixture parts, instrument enclosures, motor frames, foot pedals, and high precision machine parts etc.

Aluminum Die Casting

Zinc Die Casting

Magnesium Die Casting

Brass Die Casting (Bronze Die Casting)

Cast Metals:

1. Aluminium Die Casting: lightweight; high dimensional stability for complex shapes and thin walls; good corrosion resistance; good mechanical properties; high thermal and electrical conductivity; retains strength at high temperatures.

2. Zinc Die Casting: the easiest alloy to cast; high ductility; high impact strength; easily plated; economical for small parts; promotes long die life.

3. Magnesium Die Casting: the easiest alloy to machine; excellent strength-to-weight ratio; lightest alloy commonly die cast.

4. Copper Die Casting (Brass, Bronze): high hardness; high corrosion resistance; highest mechanical properties of alloys die cast; excellent wear resistance; excellent dimensional stability; strength approaching that of steel parts.

5. Lead and Tin Die Casting: high density; extremely close dimensional accuracy; used for special forms of corrosion resistance.

Maxtech is a professional die casting foundry in China. We offer a reliable and low cost die casting solution for materials of aluminum, zinc, magnesium, copper alloy (brass and bronze)

We support technical standards of metal casting, includes: ASTM, ANSI, SAE, DIN, and BS.

We also provide the following services:

1. Metalworking Service, CNC Machining and EDM Machining Service

2. Heat Treatment:

Hardening, Annealing, Normalizing, Stress Relieving, Softening, and Graphitization

3. Surface Treatment:

Metal Polishing (Metal Mirror Polished, Brushed Metal Finishing), Shot Blasting, Sandblasting, Spray Painting, Powder Coating, Thermal Spraying, Anodizing, Chrome Plating, Nickel Electroplating / Electroless Nickel Plating, Hot-Dip Galvanizing, Copper Plating, Phosphorizing, Electrophoresis and Passivation

4. Assembly

5. Packing

6. Testing Report, QC Report